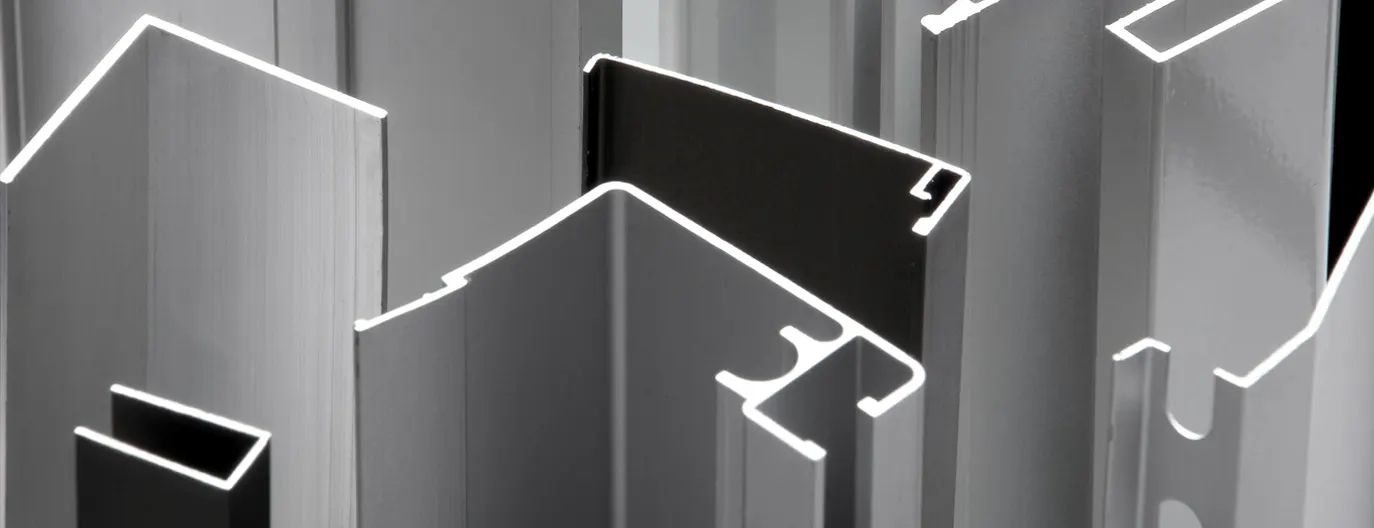

Enhancing Aluminium with Powder Coating for Durability and Aesthetics

Aluminium boasts inherent corrosion resistance, but a protective coating can elevate its performance and visual appeal. Among various finishing methods, Powder Coating stands out as a durable and aesthetically pleasing choice for aluminium extrusions.

The Powder Coating Process:

Powder Coating involves applying a protective powder coat to the surface of aluminium extrusions, enhancing their resistance to corrosion and weathering.

Surface Preparation:

Proper surface preparation is essential to ensure the coating adheres effectively and offers optimal protection. This process removes contaminants like grease, oils, surface oxides, and foreign particles, ensuring a secure bond between the coating and the metal. Unlike liquid coatings, Powder Coating doesn't require binding solvents, making surface preparation even more critical to prevent flaking.

Powder Application:

An electrostatic spray gun is used to apply the powder, which carries a positive charge. This charge causes the powder to bond with the electrically-grounded extrusion surface.

Curing Process:

The coated extrusions are placed in a curing oven, where the powder melts uniformly, forming a hardened, protective layer.

Cooling:

After baking in the oven, the extrusions are cooled, resulting in a smooth, hardened coating that firmly adheres to the surface.

Benefits of Powder Coating:

1. Aesthetic Versatility:

1. Aesthetic Versatility:

Powder Coating offers a wide range of color options and textured finishes, enhancing the visual appeal of aluminium. Unlike anodizing, which typically provides an 'aluminium' appearance, Powder Coating allows for diverse color and texture choices.

2. Environmental Friendliness:

This method is eco-friendly as it doesn't require chemical solvents like liquid coatings. It's a cleaner and more sustainable choice.

3. Durability:

Powder Coating forms a thick and robust bond with aluminium, minimizing the risk of chipping, peeling, or flaking. It provides lasting protection against corrosion and weathering.

4. Efficiency:

Powder Coating produces less waste because oversprayed powder can be collected and reused, minimizing material wastage.

In summary, Powder Coating is a superior choice for enhancing aluminium extrusions. It not only provides enhanced durability and corrosion resistance but also offers